Take you to understand the characteristics of sand casting process

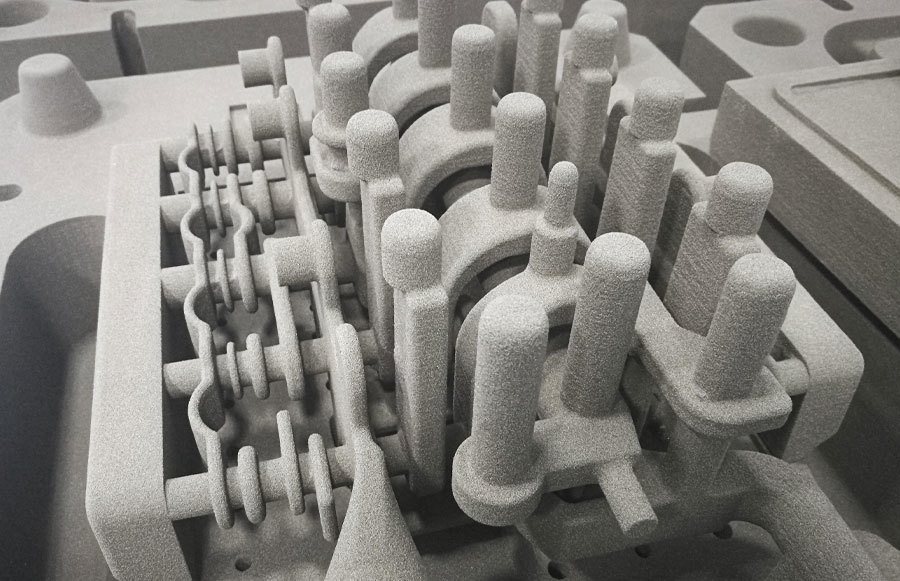

Sand casting is one of the common casting methods, and it is also one of the casting methods with low manufacturing investment and low production cost. Sand casting process is simple, easy to operate, suitable for all kinds of different materials and sizes of casting manufacturing. This article will introduce in detail the process steps, operation process and advantages and disadvantages of sand casting.

1. Process steps of sand casting

(1) Determine the shape and size of the parts that need to be cast, and design a reasonable casting plan, including taper, fillet and other lofting data.

(2) According to the casting plan, select the appropriate mold material and particle size sand mold, and the corresponding sand core.

(3) Place the template in the mold, fill the corresponding sand mold material, compact and vibrate to make it completely fit the template to ensure the accuracy of the casting.

(4) After opening the mold and taking out the template, assemble the two sand shells into a sand core, and place the sand core in the correct position.

(5) Pour the molten metal into the sand mold until the entire sand mold cavity is filled.

(6) After the casting is cooled and solidified, take it out of the sand box and clean and trim it.

2. The operation process of sand casting

(1) first prepare the template, generally based on clay or wood mold;

(2) Make sand mold according to the template, that is, mix fine sand and clay evenly, add water to make mortar with sufficient viscosity to form, and then pour it into the mold for compaction and vibration to remove voids and burrs;

(3) Set up additional parts such as the casting port and exhaust hole in the sand mold, and pay attention to the rationality of the position and size;

(4) After the sand mold is dry, assemble the two molds, and then put the core in;

(5) Slowly pour the metal material heated to the molten state into the mold to fill the entire mold cavity and maintain a certain inclination to prevent bubbles;

(6) Wait until the metal solidifies, take out the entire mold, and polish or grind the surface where needed.

3. Advantages and disadvantages of sand casting

(1) The sand casting process is simple, does not require special equipment and tools, and has high technical requirements, and is easy to master and operate.

(2) Low cost, high production efficiency, suitable for single-piece and small batch production, and can greatly reduce casting costs.

(3) Defects are prone to appear in the sand mold production process, such as sand holes, pores, etc., which need to be repaired and treated, affecting quality and time.

(4) Limited by the quality of sand mold materials and the number of sand cores, it is difficult to manufacture complex parts with high precision, and it is not suitable for the production of parts with high surface accuracy, strength and density requirements.

In short, sand casting is a simple and effective casting method with simple process flow, convenient operation, low cost and wide applicability. However, due to the limitations of materials and equipment conditions, there are also some shortcomings and limitations. In practice, it is necessary to choose the appropriate casting method according to the specific situation to achieve the appropriate effect.

Key words:

Recommend News

Share To